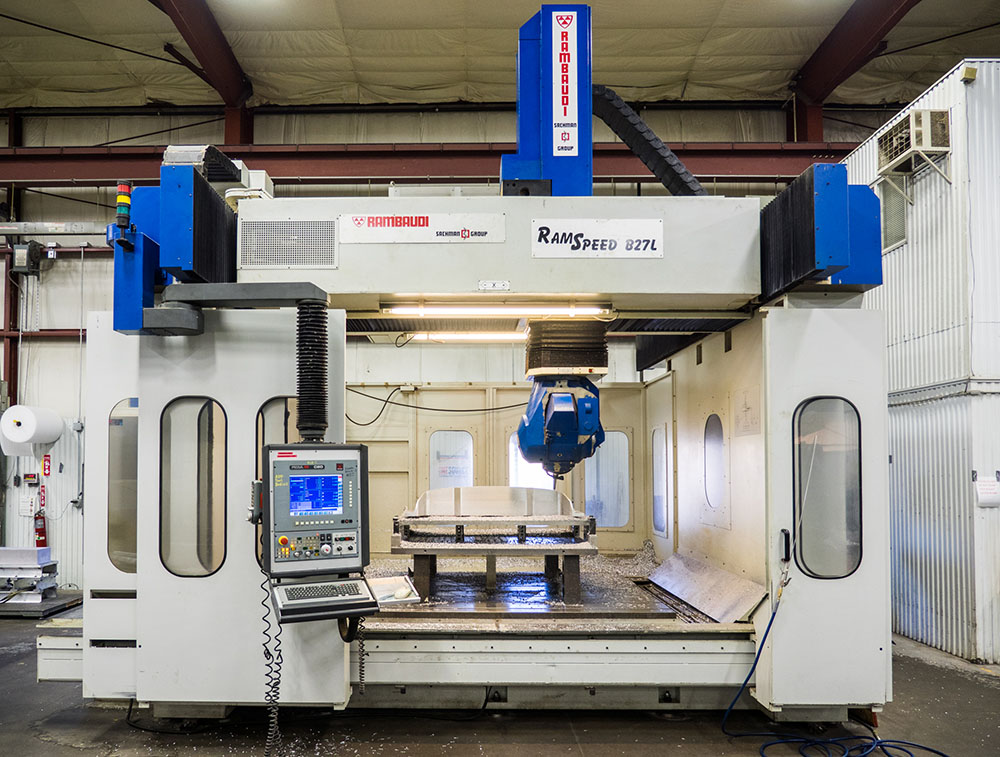

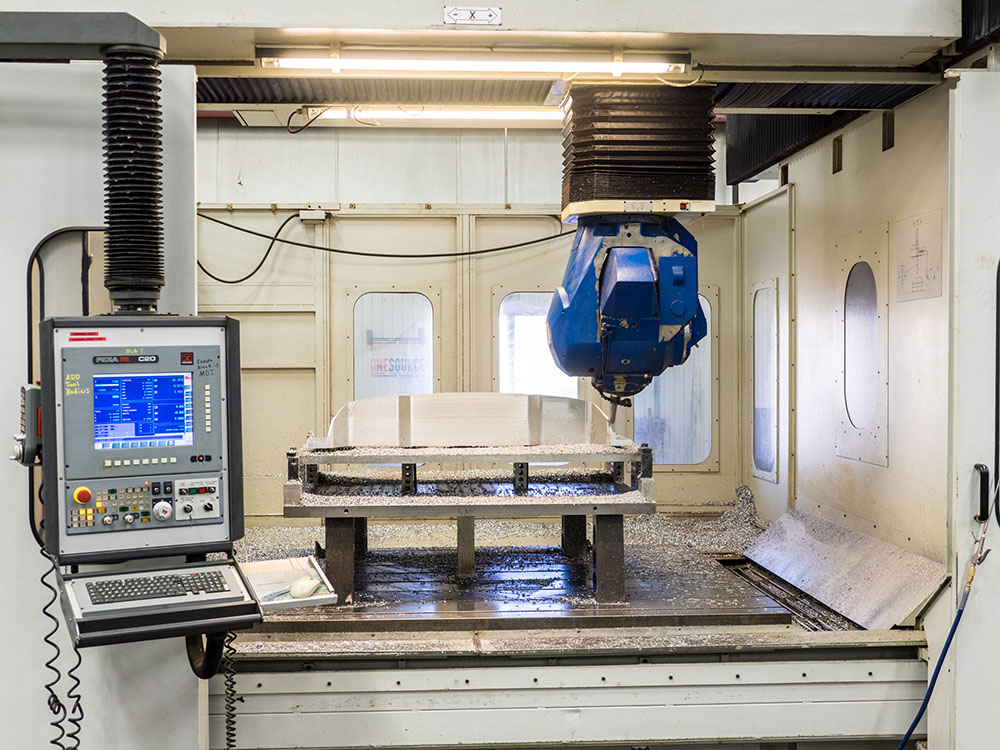

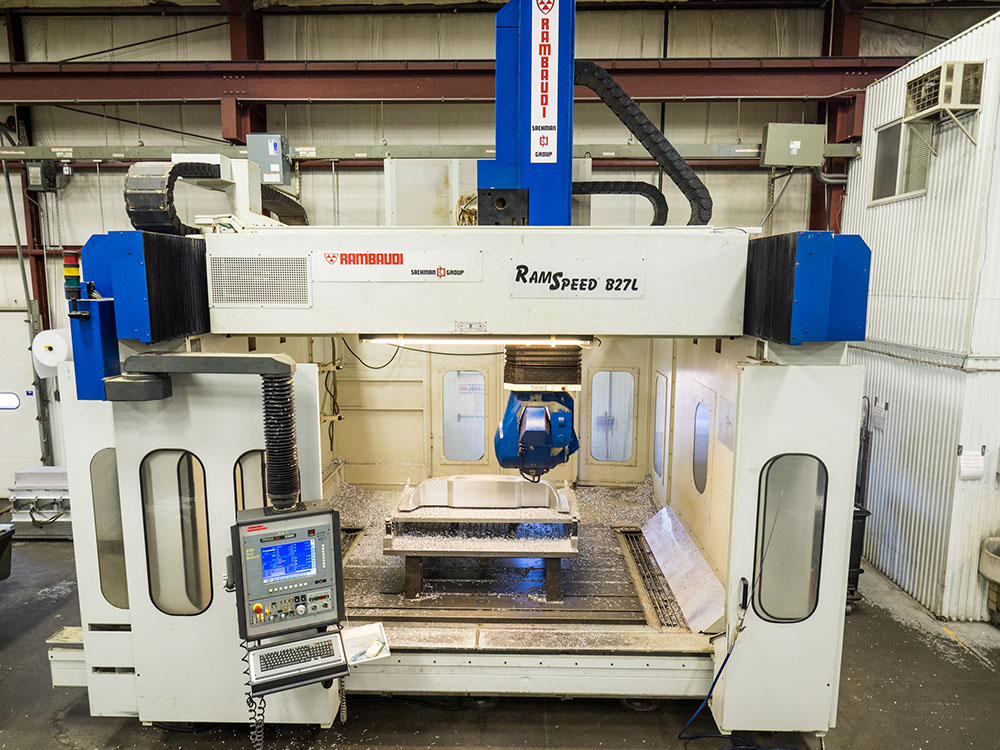

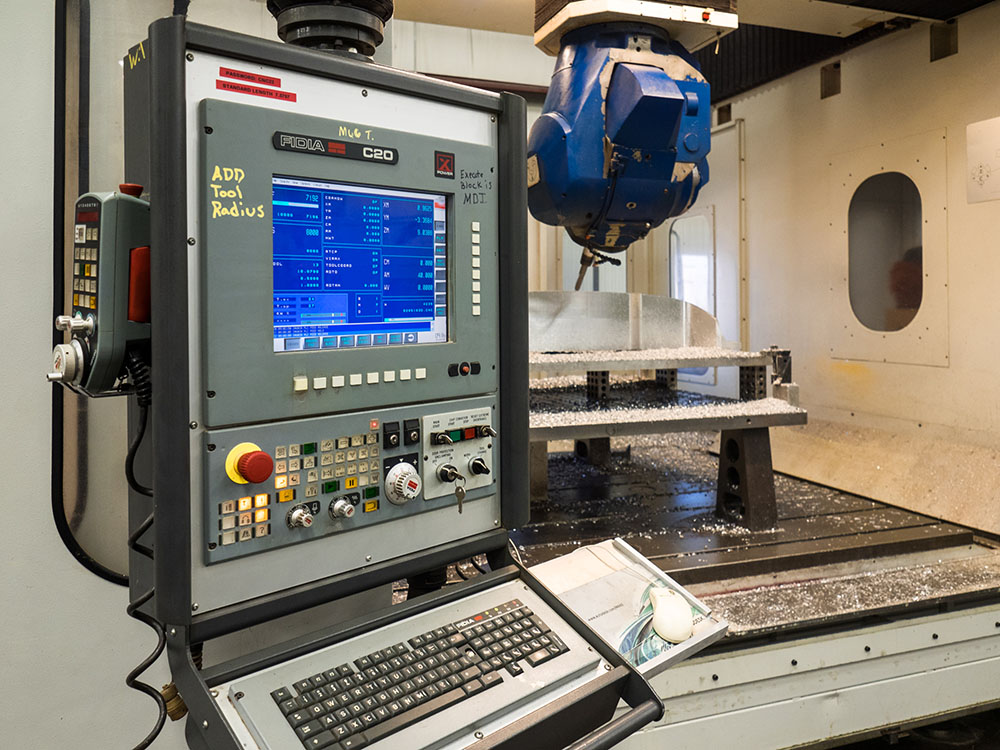

Our main custom mold shop is 15,750 sq ft, temperature controlled facility built in 1999. At this time it has 13 CNC which includes the 5 axis, 2 Overhead cranes, Gundrill, Boring Mill and new fork truck. Most of our CNC machines are installed with a probe system for dimension checks and accuracy. American Tool has large CNCs to fit large machining needs. ATE specializes in large, deep, complex, intricate, and precise molds. We also offer mold repair and mold revisions.

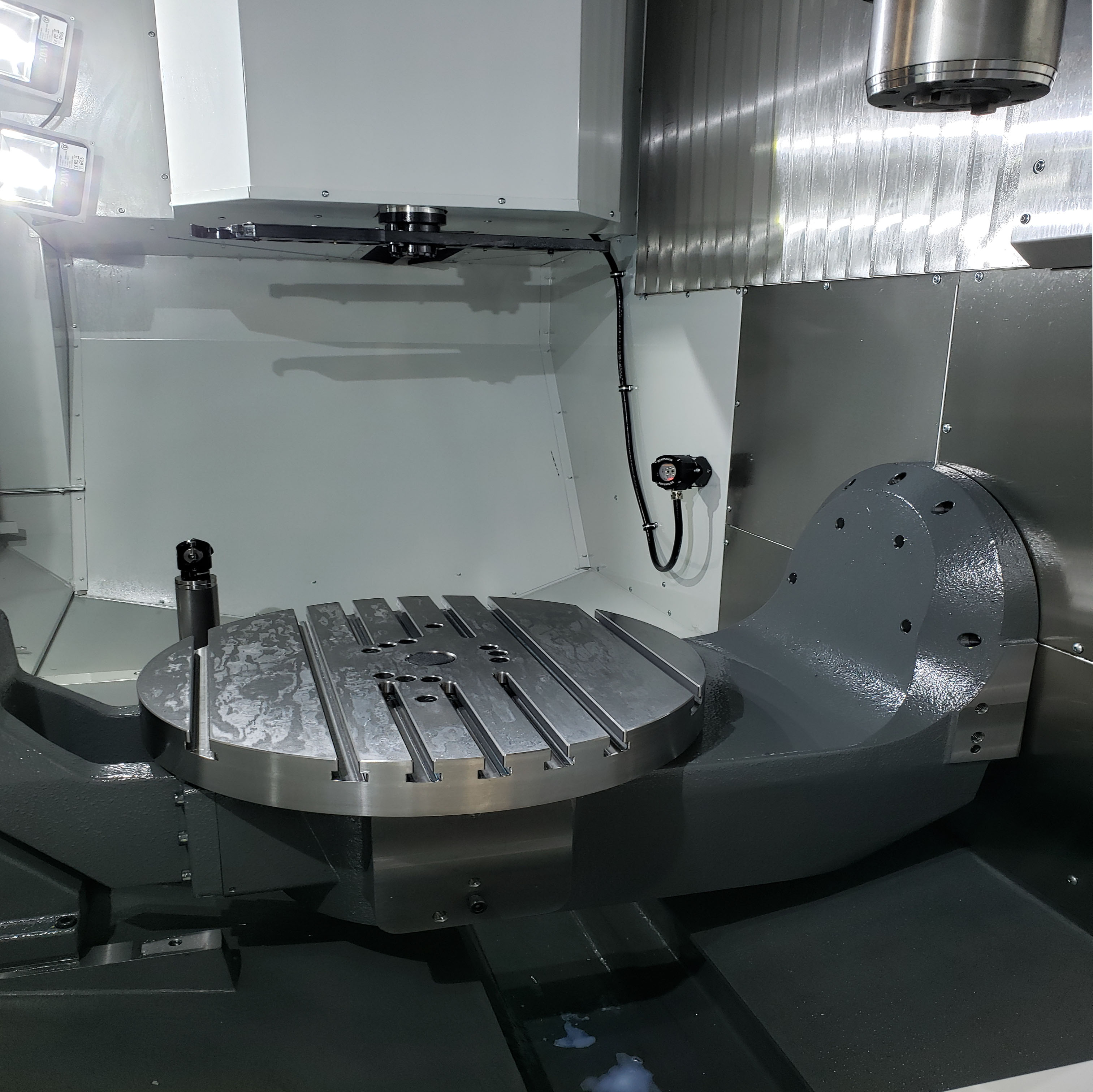

HAAS UMC 1000ss

Travels- X AXIS - 40" Y AXIS - 25" Z AXIS - 25"

C AXIS ROTATION - 360° ROTATION

B AXIS TILT - (-35°) to (+110°)

PLATTER DIAMETER - 25"

CNC- Awea Bridge Mill

Travels: X -86”, Y- 160”, Z- 38”

#50 Taper- 8,000 RPM

Coolant thru spindle and Renishaw Probing

CNC- 2015 Mighty Viper

Travels: X- 80”, Y- 39”, Z-47”

#50 Taper- 8,000 RPM

Coolant thru spindle and Renishaw Probing

CNC-2014 HAAS VF-4

Travels: X-50”, Y- 20”, Z-25”

#40 Taper – 10,000 RPM

Coolant thru spindle and Renshaw Probing

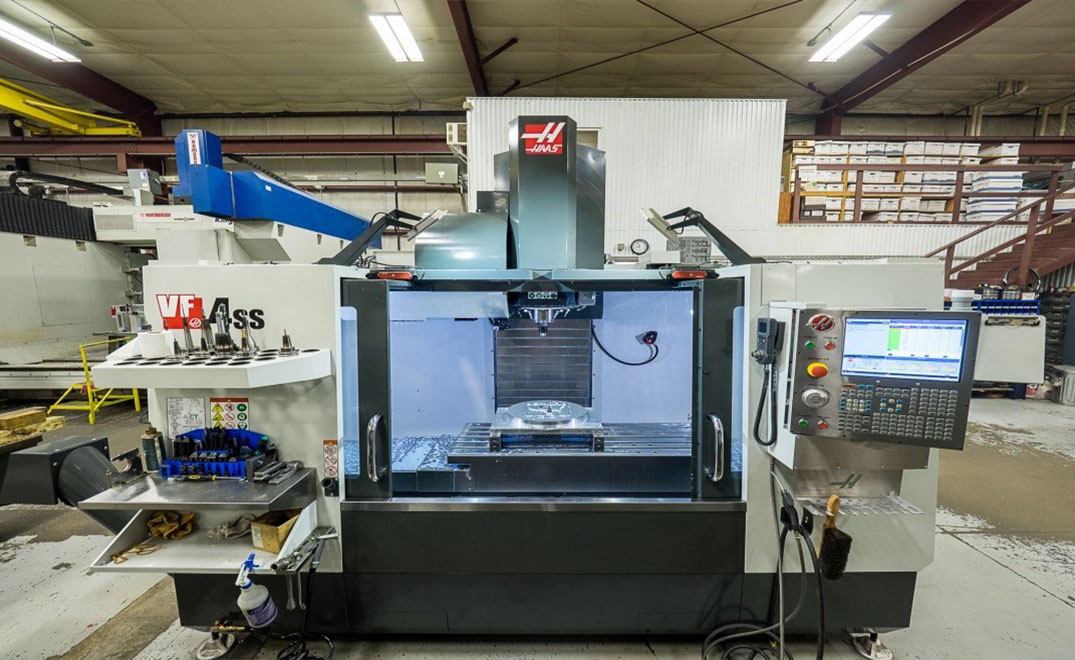

CNC- 2017 HAAS VF-4 SS

Travels: X-50”, Y- 20”, Z -25”

HAAS connect- 12,000 RPM

Coolant thru spindle and Renshaw Probing

CNC-2015 HAAS VF-9s

Travels: X-80”, Y-40”, Z- 30”

#40 Taper - 12,000RPM

Coolant thru spindle and Renshaw Probing.

CNC-2014 HAAS VF-9

Travels: X-80”, Y-40”, Z- 30”

#40 Taper - 10,000RPM

Coolant thru spindle and Renshaw Probing

CNC-Leadwell

Travel: X- 50”, Y-30”, Z-28”

#50 Taper - 6,000 RPM

CNC-Takumi

Travels- X-86”, Y -42”, Z- 37”

#50 Taper- 6,000 RPM

Gundrill Cincinnati Gilbert Gun Drill machine

Max Drill depth 96” x 1.5” DIA. Hole

CNC Lathe- 2014 HAAS ST

Travels- X-21”, Z- 26”

3,400 RPM

Automatic Tool Presetter Programmable Tailstock – Renishaw Probe

Machines not pictured at the mold shop

CNC - KAO Ming Bridge Mill - Travels- X-120”, Y- 60”, Z- 46.5” -#50 Taper – 3,000 RPM

CNC - Fadal TRM- Tavels - X-30”, Y-14”, Z- 12” - #40 Taper- 4.500 RPM

Summit NC Horizontal Boring Mill - Travels- X-60”, Y-40”, Z -62” - #50 Taper – 3,000 RPM

Manual Machines include – 2 Bridgeports, 2 Radial drills, 1 Engine lathe, and Speed drills.

American Tool also specializes in mold repair and revisions.

Pictured is Tom Lemon. Welding expert at American Tool & Engineering.

Pictured is Pam Mai. She is an expert Polisher at American Tool & Engineering.