Engineered Molds to meet the increasing demands of today’s Plastics Industries.

Our highly skilled Designers engineer molds to exact specifications.

Designers will provide you with weekly progress reports of you project along with complete 3D & 2D mold design.

From the time your mold is ordered to the time the mold is complete, dedicated professionals guide your project through every phase of the operation.

Engineering Design

Faro Arm

Compares real life scan of mold to the original 3D design.

3D & 2D Design

Designers use part data supplied by the customer to engineer the mold.

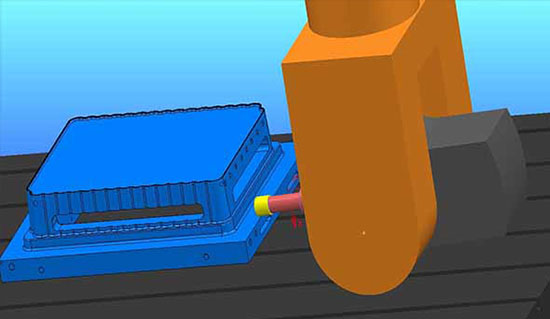

Programing

Powermill CAM software provides comprehensive milling strategies

Quality Control

All molds at American Tool & Engineering are inspected before shipment.

Pictured mold being scanned at American Tool & Engineering.

Faro Arm

Compares real life scan of mold to the original 3D design.

CMM quality report

Enabling faster, more accurate, compelling and useable 3D documentation

Accelerating execution timelines

Minimizing in field 3D documentation and measurement times.

Pictured is Justin Shirah a Designer with a 3D and 2D model

3D & 2D Design

Designers use part data supplied by the customer to engineer the mold. Once the 3D process is complete then mold data is sent for customer approval. Customer will send 3D approval back to the designer then the 2D design starts. When 2D design is complete it is sent to the customer for approval. Designers can engineer complicated molds with lifters, slides, cylinders, and tight tolerances.

SOLIDWORKS 3D CAD Software Delivers Powerful Design Functionality

Molds Are Designed By Customer Specifications

Upon Completion Of Design All Data Is Sent For Customer Approval

Weekly Progress Reports

Customers Own Mold Data

Programing

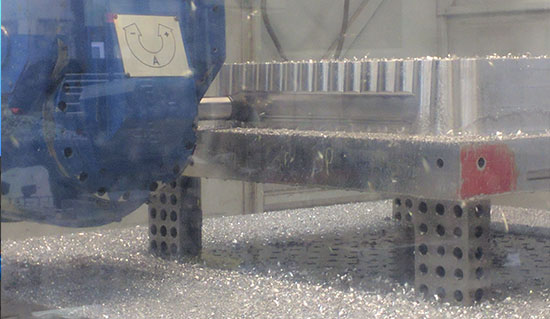

5 Axis Cutting

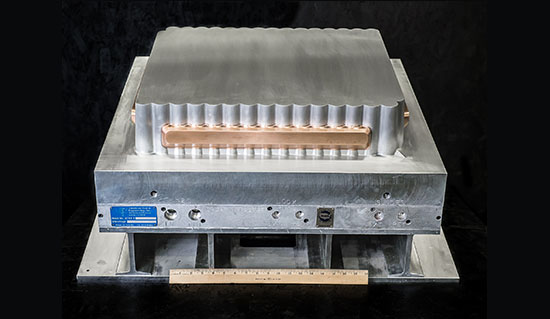

Finished Product

Programing

Program Software listed below

Powermill CAM software provides comprehensive milling strategies for high-speed 5-axis

Lemoine CAM software provides comprehensive milling strategies for high- speed 5-axis

Sufcam is a CAD CAM software for 3D milling, mill turn, multi axis machining and 3D amongst other unique features

Quality Control

Quality Control

All molds at American Tool go through a rigorous inspection before shipment. Molds are inspected by our quality control team. Inspection sheets are signed off and sent to customer upon shipment. Mold quality and accuracy are the most important things to American Tool & Engineering. ATE strives to be the best in the Industry.